Behind Every Sip, there’s a Pump Doing the Hard Work. From the milk in your morning coffee to the juice in your fridge, there’s a complex process that ensures beverages reach your glass safely, hygienically, and efficiently. One silent hero in this process is the hygienic pump — the powerhouse that moves liquid products through every stage of production. In the food and beverage industry, efficiency, cleanliness, and consistency are not options. And that's where the correct beverage processing pump comes into play. The right pump doesn't just transfer fluids; it maintains product quality, saves downtime, conserves energy, and maintains industrial regulatory compliance with rigorous hygiene standards. This blog digs into how sanitary pumps work in the beverage production process, the types of pumps ideal for these applications, and how improving your pumping system can significantly enhance your overall process efficiency and accuracy. Let’s discuss how to move smarter — not faster — with the proper food processing and beverage pumps.

Why Pump Selection Matters in Food & Beverages Production

Pumps are not merely devices for transferring liquids. They are an essential component of ensuring product sterility and consistency. Utilizing the improper beverage pump may result in issues like:

- Damage to the physical property of the product (particularly in sensitive or viscous fluids)

- Irregular flow and pressure

- Leaks and contamination

- Increased energy usage

- Downtime and excessive maintenance costs

The correct pump works to address such problems, performing a smooth transfer of liquids and semi-solids in a clean and efficient process. Fristam pumps are designed with all of these considerations in mind, making them ideal for any modern Food & Beverages processing setup and improve production efficiency.

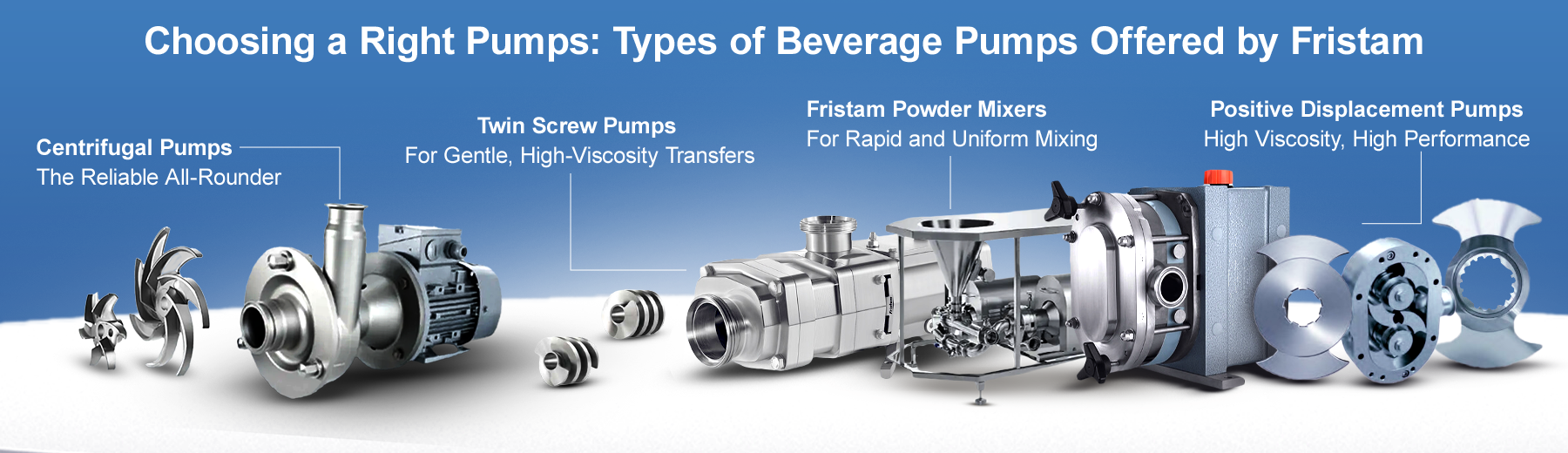

Choosing the Right Pumps: Types of Beverage Pumps Offered by Fristam

Fristam's range of beverage pumps are designed to meet the special needs of various products and processing applications. Below are the types of beverage pumps offered by Fristam to improve production efficiency:

Centrifugal Pumps – The Reliable All-Rounder

Fristam's FP Series centrifugal pump is ideal for conveying low to medium-viscosity liquids like water, milk, juice, and beer. They provide:

- Flow rates of up to 550 m³/h

- System pressures of up to 25 bar

- Discharge pressures of up to 15 bar

- Viscosities of up to 800 mPa.s

Their open impeller design provides gentle product handling, energy-efficient operation, and low maintenance. These pumps are commonly found in dairy, brewing, and beverage factories.

Twin Screw Pumps – For Gentle, High-Viscosity Transfers

Our FDS Series twin screw pump is a breakthrough. Developed from scratch to improve on traditional twin-screw technology, these pumps provide:

- Capacity to handle high and low viscosity fluids

- Capacity to operate CIP and production with a single pump

- Gentle product handling of 'sensitive' products such as sauces, syrups, and yogurt

- Simple maintenance and compacted construction

This type of beverage pump is ideal when product integrity and flexibility are the main concerns.

Positive Displacement Pumps – High Viscosity, High Performance

The FKL Series Positive Displacement Pump is well-suited for thick, sticky, and chunky goods. These food and beverage pumps are capable of:

- Pumping products up to 1,000,000 cps in viscosity

- High-pressure usage

- Delicate movement of goods such as pastes, jam, dough, or chocolate

These pumps have a smooth, non-pulsating flow and are suitable for delicate, high-value products.

Fristam Powder Mixers – For Rapid and Uniform Mixing

Along with liquid transfer, Fristam has Powder Mixers (PM and PMV series) that handle dry and wet ingredient mixing:

- Process powder input up to 10 t/h

- Break down ingredients to dissolve, emulsify, and homogenize with repeatable results

- Decrease manual work and increase consistency

- Fully CIP and SIP compatible

These powder mixers are common for syrup blending, milk powder reconstitution, and beverage premix manufacturing.

- Minimal Energy Saving: Efficient motors using VFDs adjust speed to minimize power consumption and lower operational costs.

- Hygienic Design: Smooth, crevice-free, CIP/SIP-compatible pumps meet hygiene regulations, reducing cleaning time and contamination risk.

- Less Downtime: Durable builds and low-maintenance designs keep operations running longer.

- Material Quality: Food-grade stainless steel prevents corrosion and ensures durability and safety.

- Versatility: Suitable for both low- and high-viscosity products.

- Regulatory Compliance:Pumps meet EHEDG and 3-A standards for hygienic processing and food safety.

Applications of Fristam Pumps in the Indian Market

In India's rapidly growing food and beverage sector, there's rising demand for hygienic and reliable equipment. Fristam’s pumps are widely used by Indian manufacturers across industries like:

- Dairy (milk, ghee, yogurt)

- Beverages (juices, soft drinks, flavored water)

- Breweries (beer, cider)

- Confectionery and bakery (syrups, fillings, batter)

- Sauces and condiments (ketchup, mayonnaise, chutneys)

Conclusion

The food and beverage industry needs more than just reliable pumps — it needs hygienic, efficient, and versatile systems to meet modern demands. Fristam’s range of beverage processing pumps offers top-tier performance with hygienic designs. If you're looking to improve your production efficiency, reduce downtime, and maintain top hygiene standards, Fristam has the right solution for you.