A Few Highlights of the Case Study

One of our India’s top clients from food manufacturing, with a wide range of Ready-To-Eat (RTE) foods, beverages, and authentic Indian products under its belt, had been experiencing problems with its recently installed gravy production line. They required an efficient and dependable method of mixing cooked vegetables, powders, and hot liquids and needed to ensure consistency and product quality.

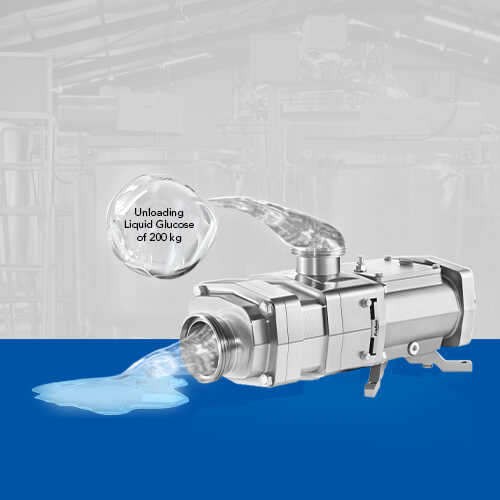

Fristam fixed the issue with a tailored Powder Mixer Skid, combining the Fristam FSP 3532 Shear Pump and the Fristam FDS 2-3 Twin-Screw Pump. The outcome: enhanced mixing efficiency, lower production time, and always high-quality gravy products.

Where the Problems Began?

The customer originally employed tank-mounted mixers and agitators, and even attempted manual mixing for their gravy manufacturing. Nevertheless, these procedures resulted in some issues:

- Inconsistent Blending: Unsteady blending of vegetables, powders, and liquids led to a non-homogeneous mixture.

- Long Process: Mixing was more time-consuming than anticipated, which resulted in production delays.

The current machinery did not possess the shear force and consistency required to mix solid ingredients with liquids effectively. An inline mixing solution that possessed high viscosity handling and gentle processing was the only way out.

Finding the Right Solution

Based on the analysis, Fristam suggested the Powder Mixer Skid with the following components:

1. Fristam FSP 3532 Shear Pump:

- 1011 Stato- Rotor combination with a high speed.

- For high-viscosity blending and good mixing.

- 11 kW, 2-pole motor for effective shear action.

2. Fristam FDS 2-3 Twin-Screw Pump:

- For handling high-particulate gravy mixes.

- 7.5 kW, 8-pole motor for smooth transfer of viscous products.

- Gentle processing of vegetables and dry fruit chunks without breakage.

Why This Configuration?

- Efficient Solid-Liquid Mixing: Manages the large proportion of solid ingredients to liquids.

- Better Product Quality: Provides homogenous uniform texture and consistency.

- Shorter Processing Time: More rapid mixing and less downtime.

- Hygienic Design: Completely CIP-compatible, food safety compliant.

- Space-Saving and Durable: Designed to save maximise space while ensuring long-lasting performance.

Implementation

The Fristam team collaborated with the client’s engineering team to have a seamless process. Major milestones involved:

- Equipment Delivery and Installation: Placing the Powder Mixer Skid in the current production line.

- Pipe Optimisation: Fine-tuning for free inlet and outlet flow.

- Performance Testing: Ensuring efficiency through actual product tests.

- Training: Training operators at the site on use and maintenance.

Challenges & Solutions

- Dealing with Large Particles Sizes: Altered the pump settings to fit non uniformity cut vegetables, tomatoes, dry fruits, leafy materials, and coarse spices to endure high particular load.

- Maximising Viscosity Range: Modified the rotor-stator setup for different gravy thicknesses which maintain the Viscosity range from 10,000 to 200,000 cP

Measurable Impact & Results

| Parameter |

Before (Traditional Method)

|

After (Fristam Powder Mixer) |

| Mixing Time | 4-5 hours | 1-2 hours |

| Product Consistency | Inconsistent | Uniform and stable |

| Maintenance Efforts | Frequent breakdowns | Minimal maintenance |

| Hygiene and Cleaning | Manual, time-consuming | Fully CIP-compatible |

| Downtime | High | Reduced significantly |

Key Achievements

- Time Savings: The new installation saved mixing time by close to 50%.

- Increased Efficiency of Production: More rapid mixing facilitated higher throughput.

- Consistency of Product Quality: Consistent mixing ensured product texture and flavour consistency from batch to batch.

- Lower Maintenance: Low wear and tear, which meant lower maintenance costs.

- Better Hygiene: CIP compatibility enhanced hygiene, a requirement for food safety.

Lessons Learned

- Customisation is Key: Having the pump configuration suited to the particular gravy formulation was fundamental.

- Blended Solutions Deliver Optimal Results: Shear and twin-screw pump integration provided the best performance.

- In-Plant Trials Are Crucial: Demos of actual recipes at the client’s plant guaranteed the solution.

The Way Forward

Surprised by the result, the client intends to roll out the Fristam Powder Mixer Skid to other gravy-making lines. The efficiency and consistency guaranteed in the proof have established the solution as a go-to for future expansions.

Fristam’s Powder Mixer Skid has revolutionised the client’s gravy production process with its unparalleled efficiency, consistency of product, and cleanliness. The synergy between high-shear mixing and sound pumping technology made it a perfect candidate for the food industry’s stringent demands.

Upgrading to the Fristam Powder Mixer Skid has created a new benchmark for efficiency in production and quality of products for the client, demonstrating the worth of innovation and reliable mixing technology in food processing.