A Few Highlights of the Case Study

A food industry client had a big challenge. They needed to charge 50–100 kg of powder into very large water tanks of 10,000 and 20,000 litres. To do this, workers had to carry heavy bags up to 20 meters and pour them into the tanks. The process took 25–35 minutes for each batch. It required 2–3 people and was tiring, slow, and inefficient.

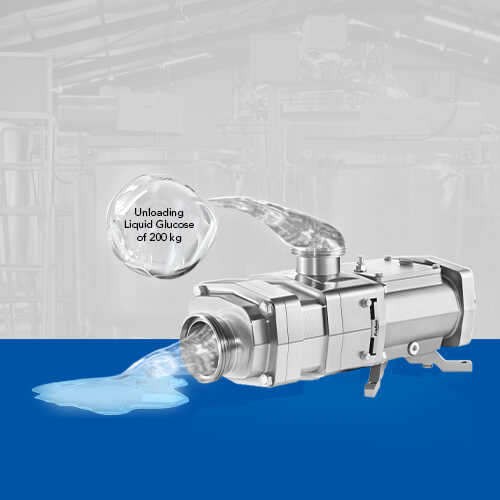

We introduced the Fristam Powder Incorporator (PE) with the FZK 20 pump and added a hopper. With this setup, a single operator could now handle the charging process in just five minutes at floor level. Production became faster and safer, labour costs were reduced, and the workflow became smoother and more reliable.

Where the Problems Began?

The client was manually charging powder into their tanks, which caused several issues:

- Heavy lifting: Workers had to carry 50–100 kg bags to heights of up to 20 meters.

- Slow process: Each batch took too long, creating delays in production.

- High manpower needs: Two to three workers were required for each batch, which increased labour costs.

- Safety risks: Carrying heavy bags up high puts workers at risk of injury and fatigue.

The manual method was clearly inefficient, inconsistent, and risky. The client needed a solution that would speed up the process, reduce the number of people required, and make the operation safer.

Research & Insights

Our team spent time on-site to understand the problem fully.

- the process: We observed workers lifting and pouring powder repeatedly. It was clear that the process was tiring and slow.

- Timing and manpower study: Each batch took 25–35 minutes and 2–3 operators. This highlighted wasted time and unnecessary manpower usage.

- Identifying bottlenecks: The main delay was moving powder bags to the tanks’ height. This not only slowed production but also caused worker fatigue.

Key Insight: Automating powder charging at the floor level would allow one person to handle the process efficiently. This would save time, reduce labour, and improve safety.

Finding the Right Solution

After analysing the situation, we recommended the Fristam Powder Incorporator FZK 20 with a hopper.

- Hopper design: Made it easy to load powder at floor level without lifting heavy bags.

- Pump efficiency: The FZK 20 pump ensured smooth, consistent powder charging.

- One-person operation: Reduced manpower from 2–3 people to just one.

- Faster processing: Each batch now took only five minutes.

- Safer work environment: Operators no longer need to lift heavy bags to high tanks.

This solution addressed all major challenges. Production became faster, safer, and more reliable.

Implementation Process

We implemented the solution step by step:

- Installation: The incorporator and hopper were set up at floor level for easy access.

- Calibration: The pump flow was adjusted for consistent powder transfer into 10kl and 20kl tanks.

- Trial runs: We ran multiple batches to ensure one operator could handle each batch efficiently.

- Training: Operators were trained on using the system safely and maintaining it properly.

Challenges

- Hopper alignment: Needed minor adjustments to match tank positions.

- Staff hesitation: Workers were unsure about the new system at first, but live demonstrations helped them gain confidence.

Measurable Impact & Outcomes

The Fristam Powder Incorporator had immediate benefits:

| Parameter | Before (Manual) | After (Fristam FZK 20) |

|---|---|---|

| Manpower Required | 2–3 operators | 1 operator |

| Time per Batch | 25–35 minutes | 5 minutes |

| Production Efficiency | Limited | Much higher |

| Safety | Risk of injury | Safe at floor level |

| Operational Bottlenecks | Frequent | Almost eliminated |

Results

- Big reduction in labour and effort.

- Faster and more consistent production.

- Safer work environment with less fatigue.

- The time saved allowed staff to focus on other tasks.

- Overall production efficiency improved significantly.

Lessons Learned

- Tailored solutions work best: The combination of the hopper and FZK 20 pump allowed one person to manage each batch easily.

- Live demonstrations build confidence: Seeing the system in action helped staff trust and adopt it quickly.

- Design tweaks matter: Future improvements, like preventing water from entering the hopper, could make the process even better.

- Automation reduces fatigue: Operators experienced less physical strain and worked more efficiently.

The Next Steps

Given the success of this project, similar solutions can be applied elsewhere:

- Scaling the system for larger tanks or multiple batches.

- Using it for different powders or granular materials.

- Applying the same approach in pharmaceuticals, beverages, or the chemical industries.

- Integrating automation and monitoring systems for fully controlled powder handling.

Conclusion

The Fristam Powder Incorporator FZK 20 transformed a slow, tiring, and inefficient process into a fast, safe, and reliable one. Charging time dropped from 25–35 minutes to just five minutes. Manpower requirements fell from three people to one. Operators worked safely at floor level, reducing fatigue and injury risks. Production efficiency increased, labour costs dropped, and workflow became much smoother.

This case shows that simple, well-designed automation can save time, reduce labour, and improve efficiency without overcomplicating processes. By focusing on safety, speed, and usability, businesses can streamline operations, reduce costs, and improve overall productivity while maintaining high-quality standards.