A Few Highlights of the Case Study

One of our major client from a food processing company in India was facing serious challenges with the handling of high-viscosity food ingredient transfer, especially liquid chicory, from storage tanks to their production facility. Their current Single Screw Pump arrangement resulted in regular maintenance, long transfer times, and non-CIP compatibility.

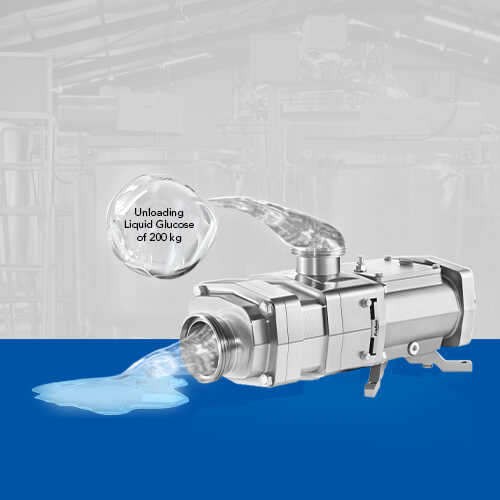

Fristam solved it with a solid solution by offering its FDS Twin Screw Pump, which significantly increased efficiency, put an end to maintenance problems, and facilitated smooth CIP (Clean-in-place ) cleaning. The outcome: decreased operating cost, enhanced hygiene, and substantially shorter transfer time—maximizing the overall production cycle.

Where the Problems Began?

The client was operating Single Screw Pumps for transferring and unloading Liquid Chicory from 50KL tanks. A few operational hurdles crept in:

- Rubber Stator Failures: Repeated damage to the rubber stator resulted in downtime and expensive repairs.

- Long Transfer Time: Product transfer was taking 5–6 hours, slowing down downstream production.

- Not CIP-Compatible: Manual cleaning involved disassembly, affecting hygiene and efficiency.

- Operational Inefficiency: Bulky pump design and maintenance raised overheads.

The client required a hygienic, time-saving, and reliable solution that would easily manage thick, sticky product and provide the benefit of automated cleaning-in-place.

Research & Insights

Fristam’s technical team made an on-site visit for an entire system audit. They performed:

- Visual Inspections of the pump running and piping configuration

- Application Analysis on the basis of viscosity, temperature (20–35°C), and pressure requirements

- Operational Review to evaluate the lost time spent during cleaning and transfer

- Product Sample Testing to ensure pump compatibility

The take-away point? The process called for high-pressure delivery with gentle handling and efficient CIP operation—neither of which was offered by the current screw pumps.

Finding the Right Solution

Given duty conditions and performance requirements, Fristam recommended 2 Nos. of FDS 2 Nos. of FDS 2-4 / 7.5kW Twin Screw Pumps with Double Mechanical Seal because of its following features:

- Processes High Viscosity (10,000 cp to 45,000 cp) with ease

- Gives 8 m3/hr @ 5 bar, and 16 m3/hr @ 2 bar for CIP

- Fully CIP/SIP Compatible, avoiding manual cleaning

- Compact Stainless-Steel Construction, saving floor space

- Low Maintenance, no rubber parts to wear out

- Sanitary Design, food-grade compatible

- Density 1.35 g/cc

- PH 4.4

Implementation

After the client’s approval, our team worked closely with the client’s maintenance and engineering departments. Steps to implementation were:

- Pump Delivery & Positioning

- Suction/Discharge Line Guidance for smooth flow

- Commissioning & Training by Fristam technicians

- Performance Testing to confirm parameters and CIP flow rate

Small problems such as straightening pipe bends and inlet height optimization were also tackled on site with the aid of Fristam’s field service engineers.

Measurable Impact & Results

The impact was apparent right after deployment:

| Parameter |

Before (Single ScrewPump)

|

After (Fristam FDS Pump) |

| Unloading & Transfer Time |

5-6 Hours | 2-3 Hours |

| Product Loss | Frequent leakage | Zero leakage |

| Downtime | High (due to stator issues) | Negligible |

| Cleaning Time | Manual, 2+ hours | Fully CIP-compatible |

| Maintenance |

Frequent Failure Rubber

Part, Stator

|

Rotating parts are SS – Less

Maintenance

|

| Pump Length | 2-3 meter |

Max 1 to 1.2 meter –

compact design

|

| CIP |

Not possible with Single

Screw Pump

|

Possible with required flow

rate and pressure – Cost

effective solution

|

| Cost Saving | No Savings | Saved 4-5 Lakhs/month |

Key Achievements

- Saved 2–3 hours per batch in transfer time

- Increased yield and throughput because of quicker product availability

- Enhanced plant hygiene with CIP-ready pumps

- No component wear to zero—no need to replace the stator

- Low noise, gentle handling of products, and maintaining product quality

- Monthly cost saving 4-5 lakhs

Lessons Learned

- Standardization across similar applications can make maintenance cheaper and easier, and simplify spare part management

- ROI through efficiency data helped secure stakeholder trust despite the higher upfront pump cost

- Technical support and training ensured the smooth uptake of new pump technology

The Way Forward

Influenced by the outcome, the customer is set to implement the solution in 2–3 additional facilities over the coming year. They’ve decided to use Fristam FDS pumps for all high-viscosity transfer operations with CIP capability.

Fristam’s FDS Double Screw Pump has changed efficiency and hygiene expectations in transferring viscous products in India’s food processing industry. With its sanitary design, delicate flow handling, CIP capability, and regulatory industrial compliances 3-A & EHEDG, the FDS pump has been a game-changer, offering long-term cost-saving and operational success.