Modern food and pharma facilities depend on systems that stay stable across long production hours. Equipment must handle different materials, maintain hygiene, and keep the flow consistent without interruption. Plants often work with a trusted pump manufacturer because reliable performance directly supports product quality. The pump manufacturing industry focuses on solutions that remain efficient in demanding environments.

Fristam Pumps is known for delivering consistent operation in these conditions. Their pumps support high hygiene, smooth flow, and simple maintenance. Teams need equipment that responds quickly and stays predictable, especially when production schedules stay tight.

Over the years, Fristam Pumps gained a strong reputation in these busy environments. Their systems stay consistent even when production feels intense. And in industries where small delays grow into bigger issues, teams rely on equipment that responds quickly and stays simple to handle.

The Need for Efficiency in Today’s Processing Units

Food and pharma plants deal with high volumes, tight timelines, and strict safety rules. A single weak point slows the entire system, and that slowdown affects overall output. Companies want systems that help them work faster while keeping maintenance light.

That is one major reason Fristam Pumps became a preferred choice. Their engineering focuses on stable flow, cleaner operation, and long running hours. People trust solutions supported by reliable industrial pump suppliers, especially ones that think long term.

What Makes Twin Screw Pumps a Better Choice

A twin screw pump works differently from many traditional pumps. Modern plants often choose a double screw pump because it maintains stable flow with minimal product disturbance. The pump handles variations in viscosity without losing efficiency. Whether the product is light, dense, aerated, or sensitive, the system maintains consistent movement. This allows plants to manage challenging formulations while keeping hygiene and performance intact.

Twin Screw Pump Working Principle

Twin screw technology allows two screws to rotate in a synchronised motion. As they turn, they form sealed chambers that carry product forward in a smooth, pulseless flow. This prevents unnecessary friction and protects ingredients during transfer.

This method remains one of the most reliable systems in hygienic spaces. It supports stable transfer and also handles low and high viscosities without trouble. Engineers appreciate the calm movement because it reduces stress on delicate materials and keeps operations cleaner.

Why This Design Truly Matters

The smooth pumping action keeps textures intact. Items like yoghurt, gels, syrups, creams, and pharma suspensions move safely through the pump. Overheating becomes unlikely, which helps plants run longer hours comfortably.

Enhanced Hygiene and Precision Seal Engineering

Hygiene stands at the core of food and pharma operations, and Fristam Pumps are designed to maintain the highest standards in hygienic processing. Every component is engineered for cleanability, including smooth internal surfaces, tight geometric tolerances, efficient drainage and an obligate industrial standards 3A and EHEDG certified. The pumps use high-grade mechanical seals and stainless steel 316L material of construction that resists corrosion. They offer strong barrier protection and support long CIP cycles. These seals minimise contamination risk, stay stable under varying pressures, and reduce residue buildup during operation. This attention to hygienic design helps plants maintain consistent product safety and integrity.

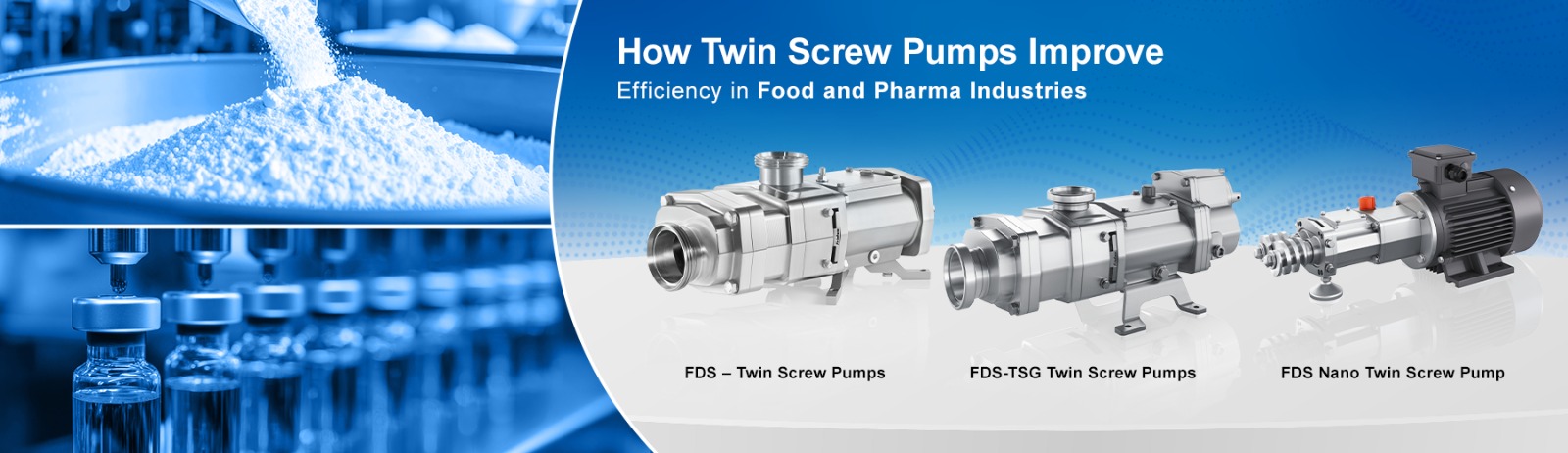

Types of Fristam Twin Screw Pumps

Fristam offers a specialised range of twin screw pumps designed for different production needs. Each model supports hygienic processing, smooth flow, and efficient handling of various viscosities. These pumps help plants manage both gentle and demanding applications with confidence.

How Twin Screw Pumps Improve Food Industry Performance

Food manufacturing involves sauces, beverages, pastes, creams, and several materials that behave differently. Plants often rely on pumps used in the food industry because they handle difficult textures. These systems support quicker transitions during recipe changes.

Twin screw pumps help teams switch from one product to another with less cleaning time. Models from Fristam Pumps handle fast filling operations and slow transfers with equal ease.

What Makes Them Practical for Food Units

- Gentle handling protects food structure

- CIP becomes simple due to smooth surfaces

- One pump works for multiple textures

- Lower downtime supports more production hours

Why Pharma Plants Prefer Twin Screw Systems

Pharmaceutical environments demand extreme hygiene, controlled movement, and minimal shear. A Pharma Industries pump must respect these conditions and must stay consistent during sensitive transfers.

Fristam Pumps delivers these advantages with precision-built systems. The pump maintains clean contact surfaces and handles syrups, suspensions, gels, and active ingredients without disturbing their nature.

Why It Fits Pharma Requirements

- Steady flow supports accurate dosing

- Stainless steel ensures top hygiene levels

- Sensitive formulations stay intact

- Cleaning cycles finish quicker, saving hours

Real Efficiency on the Production Floor

Most pharma units work with many small batches. Changeover speed affects total output. Twin screw pumps shift between CIP mode and production mode without complicated steps, helping teams save effort across the day.

Real Life Applications of Fristam Twin Screw Pumps

Food and pharma plants use twin screw technology in several areas.

- Transferring viscous syrups and pastes

- Feeding filling machines

- Loading and unloading vessels

- Handling shear-sensitive materials

- Managing products with particles

Why Fristam Pumps Stand Out?

Fristam understands hygiene, durability, and user convenience. Their pumps run long hours without performance loss. Technicians can quickly inspect the system because the design remains accessible.

Key Advantages

One important capability highlighted on the Fristam twin screw pump range is that high differential pressures are mastered without the risk of overheating, which adds more confidence during long production runs.

- Self priming

- Low pulsation and smooth output

- Strong pressure capability

- Compact build for limited spaces

- Quick seal replacement

These features help reduce long-term expenses and support stable production cycles.

Conclusion

Industries that move fast need equipment that adjusts quickly. Twin screw pumps give food and pharma plants the flexibility and stability they need. With Fristam Pumps leading innovation in this field, companies gain systems that perform better, last longer, and work more efficiently.

A plant becomes stronger when every part works smoothly. Twin screw pumps help bring that balance, making every batch safer, cleaner, and easier to manage.