FCM Colloid Mixer

The Fristam FCM Colloid Mixer is a high-performance mixing and homogenising system designed for efficient blending of liquids and particles. Known for delivering consistent, high-quality results, it is widely used across industries that demand precision mixing, including food and beverage, dairy, pharmaceuticals, chemicals and cosmetics.

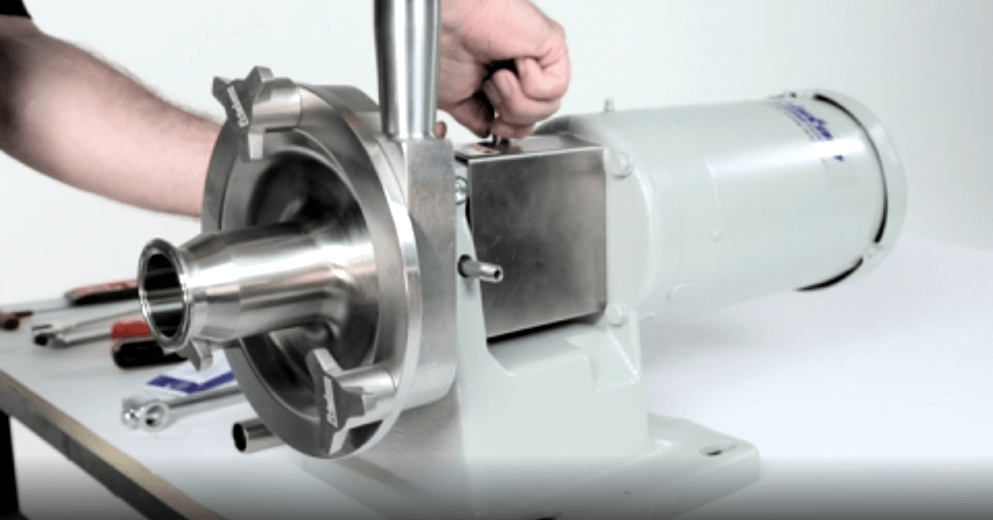

It handles liquids and particles efficiently and supports processes that require uniformity and controlled texture. The system uses a rotor-stator setup to reduce particle size and distribute ingredients evenly, which helps achieve consistent homogeneous product quality. The mixer includes an external gap adjustment lever that lets operators fine-tune shear levels without stopping production or shifting any ports. Its Clean-In-Place (CIP) design allows internal cleaning without taking the machine apart, which helps reduce downtime and maintenance.

The FCM works across many applications, ranging from simple blending to complex emulsions, suspensions, and dispersions. It is ideal for producing stable, high-quality products with improved shelf life and performance.

Technical Specifications

-

Maximum Shear Rate:

Maximum Shear Rate:

143,000 1/s -

Maximum Line Pressure:

Maximum Line Pressure:

17.2 bar -

Maximum Flow Rate:

Maximum Flow Rate:

11.4 m³/h (product),

22.7 m³/h (CIP) -

Connection Size:

Connection Size:

76 mm (3”)

-

Motor Rating:

Motor Rating:

Up to 30 kW -

Achievable Particle Size:

Achievable Particle Size:

Sub-micron -

Rotation:

Rotation:

Bi-directional

Specific Construction

The FCM uses a strong rotor and stator setup to generate high shear during operation. This design helps reduce particle size and improve overall product texture. The mixer features an external gap adjustment, allowing operators to fine-tune the mixing process without shutting down the machine. Its construction supports CIP (Clean-In-Place) cleaning and ensures smooth handling of both thin and thick products.

Application

Salient Features

High Shear Performance

The advanced rotor stator configuration generates intense shear forces that efficiently break down particles. This process improves dispersion, reduces agglomerates, and creates smooth, stable emulsions. It ensures uniform mixing even for challenging formulations that demand precise particle size control and consistent product quality.

Versatility

The FCM Colloid Mill is designed to process a wide variety of materials without compromise. It handles low viscosity liquids, semi solid slurries, and highly viscous pastes with equal efficiency. This flexibility makes it suitable for multiple applications across food, pharmaceutical, cosmetic, and chemical processing lines.

Adjustable Shear Levels

An external adjustment lever allows operators to change the rotor stator gap while the unit is running. This provides real-time control over shear intensity, particle size reduction, and final texture. It helps achieve exact product specifications without stopping production or interrupting batch flow.

Robust Construction

Manufactured using high-grade stainless steel, the FCM is built for continuous and demanding industrial use. Its solid construction resists wear, corrosion, and mechanical stress. This durability ensures long service life, reliable performance, and consistent output even under heavy operating conditions.

Easy Maintenance

The design supports quick, hands-free Clean In Place cleaning without dismantling major components. This reduces manual effort, shortens cleaning cycles, and minimises downtime between batches. Faster maintenance improves overall plant efficiency while maintaining strict hygiene and process reliability standards.

Sanitary Design

The FCM High Shear Colloid Mixer follows hygienic design principles suitable for sensitive industries. Smooth surfaces, minimal crevices, and food-grade materials help prevent contamination and product buildup. This structure supports compliance with strict hygiene requirements in food, pharmaceutical, and cosmetic manufacturing environments.

Key Applications Include

The FCM Colloid Mixer delivers dependable performance across sectors where high-quality, uniform mixing and emulsification are critical. Some of the key factors include:

Food & Beverage

Used for mixing and emulsifying components in sauces, dressings, mayonnaise, and beverages such as fruit juices or smoothies.

Dairy

Ideal for producing yogurt, milk mixes, ice cream bases, and cheese sauces where a uniform texture is required.

Pharmaceuticals

Applied in producing emulsions for creams, ointments, lotions, and various liquid formulations.

Chemicals

Used in paints, coatings, adhesives, and other industrial liquids where particle size control and consistency are needed.

Cosmetics

Suitable for creams, lotions, shampoos, and personal care products that rely on even dispersion.

Biotechnology

Used in processes involving biologics or vaccines, where controlled mixing and emulsification are part of the formulation needs.

How Does the FCM Colloid Mixer Work?

The FCM Colloid Mixer uses a high-shear rotor-stator setup to apply mechanical and colloidal forces during processing. The basic steps include:

Inlet

Ingredients enter the mixer for processing.

High-Shear Mixing

The rotor and stator generate shear that breaks particles and droplets into smaller sizes, supporting dispersion and emulsification.

Homogenization

As the mixture moves through the rotor-stator gap, it continues to emulsify, blend, and reduce particle size.

Outlet

The processed mixture leaves the system as a uniform product with fewer clumps or inconsistencies. The rotor’s high-speed movement shears liquids or semi-solids into finer particles, helping achieve consistent textures, smaller particle sizes, and stable emulsions as needed.

Key Operational Benefits

Uniform Blending

FCM mixer delivers steady and even blends for many types of products.

Faster Processing

Reduces mixing time and helps production move smoothly.

Better Stability

Improves product hold and reduces separation issues.

Easy Cleaning

Supports simple cleaning and keeps hygiene levels high.

Less Waste

Cuts down on rework and helps save material.

Benefits

Even Product Quality

The FCM helps maintain a smooth and steady consistency, ensuring a uniform result that remains consistent throughout production.

Faster Processing

It reduces the overall mixing time, helping production lines move quickly while maintaining controlled and easy-to-manage mixes.

Better Stability

The blends remain stable for longer periods, reducing the chance of separation and supporting clean, reliable output.

Lower Costs

By reducing the need for additional processing steps (e.g., cooling or additional homogenization), the FCM can lower overall production costs.

Options to Customize

-

Options to Customize

-

Adjust settings based on mixing needs

-

Fit into new or existing production lines

-

Custom flow rates and motor options