Sanitary applications require pumps to play a crucial role. From food, beverage, and dairy operations to pharmaceutical use, fluid handling must be both efficient and clean to ensure the quality and integrity of the final product. Among the many pump technologies available today, two types lead the way in sanitary processes: centrifugal pumps and positive displacement pumps.

Both pumps have their individual strengths, and identifying the difference between the two can be useful in helping businesses choose the best pump for the task. In this blog, we will break down the major differences between centrifugal pumps and positive displacement pumps for sanitary applications, and explore where each is most effective.

Understanding Centrifugal Pumps

Centrifugal pump working relies on kinetic energy. A rotating impeller is employed by it to make a fluid speed up, and this speed gets converted into flow or pressure. Centrifugal pump processes are the best for conveying large amounts of low-viscosity liquids like water, milk, juices, or thin syrups.

Benefits of Centrifugal Pump

- Non-stop Flow: Provides smooth, non-pulsating flow best suited for sensitive applications.

- Low Wear & Easy Maintenance: Fewer wearing parts result in minimal wear and simple maintenance.

- Economical Energy Usage: It functions optimally at high flows and low-viscosity fluids.

- Economical to Buy & Maintain: Typically cheaper to purchase upfront and maintain.

Applications of Centrifugal Pump Processes

- Handling low-viscosity liquids

- Clean-in-Place (CIP) systems

- Sanitary heating, cooling, or flushing systems

Fristam’s FP Series centrifugal pumps are widely used across dairy, chemical, beverage & brewing and pharmaceutical industries in India for their reliability, gentle product handling, hygienic design and regulatory compliances 3-A & EHEDG.

Understanding Positive Displacement Pumps

Unlike centrifugal pumps, positive displacement pumps move fluid by trapping a fixed volume and forcing it through the pump’s outlet. This makes them ideal for handling high-viscosity, shear-sensitive, or abrasive materials like cream, peanut butter, ointments, or sauces.

There are several types of positive displacement pumps applied in sanitary environments, including:

- Rotary Lobe Pumps

- Twin Screw Pumps

Positive Displacement Pump Uses

- Dosing and metering ingredients

- Transfer of thick, viscous, or chunky fluids

- Applications involving varying pressure conditions

- Processing delicate products that cannot withstand shear

Positive Displacement Pump Advantages:

- Consistent Flow: Provides the same flow regardless of backpressure.

- Flexible: Accommodates both high and low viscosity products.

- Self-Priming: Can manage air, which makes it particularly suitable for draining tanks and lines.

- Gentle Pumping: Reduces shear and preserves product integrity.

Fristam's FL and FL3 Series are high-quality positive displacement pumps for sanitary applications, featuring accuracy, hygiene, and power. The FL3, with its helical three-winged rotors, is especially ideal for CIP return systems, minimizing the use of a second pump.

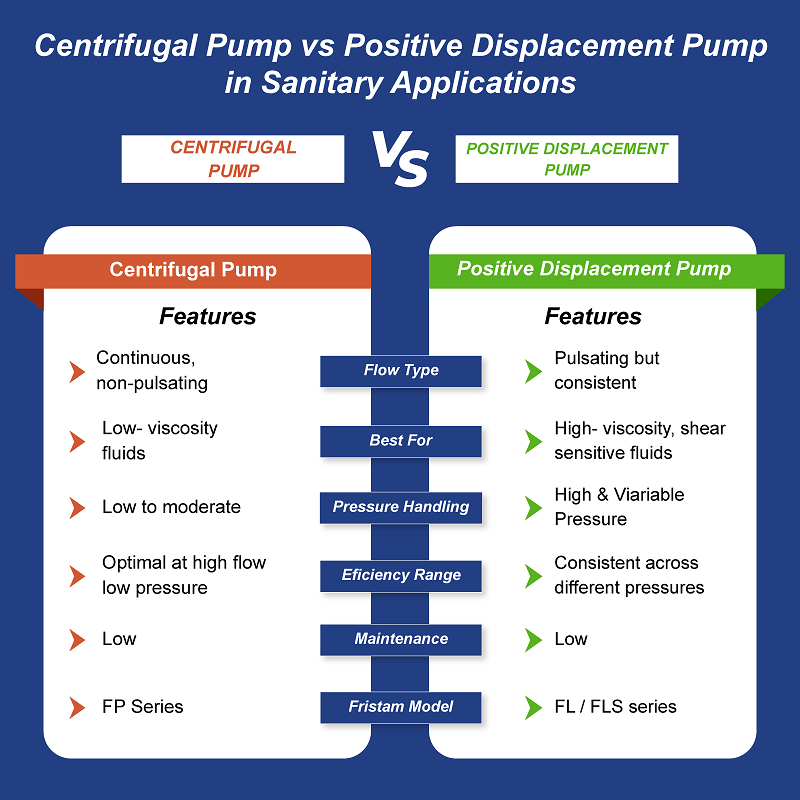

Quick Comparison: Centrifugal vs Positive Displacement Pumps

Choosing the Right Pump for Sanitary Applications

The appropriate pump selection rests on a variety of factors, including:

- Product Viscosity: Centrifugal pumps are best for thin products. PD pumps are best for thick and sticky, or chunky products.

- Flow Rates: High flows at low pressures are best for centrifugal pumps; constant flow with variable pressure is better served in PD pumps.

- Shear Sensitivity: If the product needs to be handled with care (such as in dairy or cosmetics), a positive displacement pump is the better choice.

- Cleanability and Hygiene: Fristam's centrifugal and PD pumps both conform to international sanitary standards and accommodate CIP/SIP systems.

- Total Cost of Ownership: Think not just about the initial investment but also maintenance, energy usage, and service life.

Fristam's Sanitary Pump Solutions for India

Fristam is a trusted global leader in hygienic pump manufacturing, offering a wide portfolio of pumps for sanitary applications. Whether you’re running a high-speed beverage line or dealing with high-viscosity pharmaceutical pastes, Fristam has a solution tailored to your needs.

Fristam pumps are designed for:

- Maximum hygiene compliance

- Gentle product handling

- Durability in demanding conditions

- CIP/SIP readiness

- Low total cost of ownership

Fristam's presence in India provides support to a variety of sanitary industries such as dairy, food, beverage, cosmetics, chemical, home & personal care and pharmaceutical industries.

To Sum Up

There isn't a single answer to pump selection in sanitary applications. Centrifugal and positive displacement pumps both play critical roles. Centrifugal pumps are ideal for quick, high-volume, low-viscosity processes, but positive displacement pumps benefit processing high-viscosity, high-pressure, and shear-sensitive processes.

With Fristam's superior engineering and strong range of pumps, the decision becomes less about giving up and more about maximizing your process. Upgrade your sanitary systems or build from the ground up with a new production line by relying on Fristam for precision, performance, and confidence.