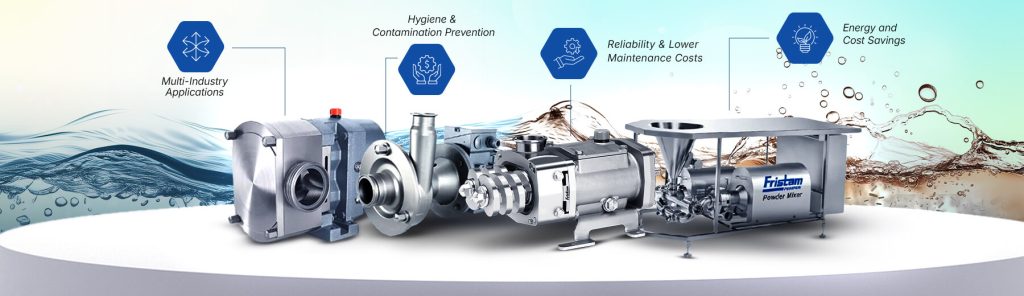

5 Reasons to Choose Fristam Hygienic Pumps for Your Applications

Today’s competitive manufacturing industries require the correct pump choice. This is more than a technical decision it has a direct impact on product safety, operating efficiency, and long-term reliability.