Choosing the Right Centrifugal Pump: Factors, Tips, and Industry Insights

October 10, 2025

Learn how to choose the right centrifugal pump for your application. Explore essential selection factors, expert tips, and the latest industry insights to enhance efficiency and performance.

That is why it is so critical to know which pump is right for your manufacturing process. The modern sanitary centrifugal pumps are not only for good performance, but also for hygiene, energy usage, and easy maintenance. This blog discusses what to consider when choosing a centrifugal pump, the various types of centrifugal pumps and why Fristam Pump’s are the most reliable pumps in the market.

What Makes Centrifugal Pumps So Important?

A centrifugal pump works by converting rotational energy (from an electric motor) into energy in the fluid being pumped. These pumps are used everywhere, from moving milk in dairies to circulating syrups, juices, or chemicals in industrial plants.

Their popularity comes from their simplicity, reliability, and versatility. When properly selected, they deliver smooth, consistent flow, handle sensitive products gently, and help maintain strict hygiene standards in processing lines.

Key Factors to Consider When Choosing a Centrifugal Pump

When selecting a centrifugal pump system, you should think about how it will fit into your operation. Here are the main things to consider

- Flow and Pressure Requirements: Always match your pump to the flow and pressure your process needs. An oversized pump wastes energy, while an undersized one can't deliver the performance you expect.

- Type of Fluid: The texture or viscosity of your product, whether it's thin like water or thick like syrup, affects how it moves through the pump. Choosing the right type ensures smooth operation.

- Material of Construction: In food and pharmaceutical applications, 316L stainless steel is the gold standard. It's durable, corrosion-resistant, and hygienic, perfect for clean-in-place (CIP) systems used in the food industry.

- Energy Efficiency: Efficient pumps reduce power consumption and long-term costs. Over time, a well-designed, energy-saving pump pays for itself.

- Ease of Cleaning and Maintenance: Pumps that can be cleaned and maintained easily, without special tools, save time and reduce production downtime

- Compliance and Safety: Make sure your pump meets relevant sanitary standards, especially if you're in industries where product safety and purity matter most.

Understanding the Different Types of Centrifugal Pumps

.

There isn't just one type of centrifugal pump. Depending on the process, you might need:

.- Single-stage pumps: Ideal for low to moderate pressure applications.

- Multistage pumps:Used for higher-pressure operations.

- Self-priming pumps: Can handle air-liquid mixtures without losing suction.

- Sanitary/hygienic pumps: Designed for food, dairy, and pharma industries where cleanliness is critical.

Among centrifugal pump manufacturers in India and around the world, Fristam has built a reputation for precision engineering, reliability, and hygiene.

Fristam's Centrifugal Pumps: Setting the Standard for Quality and Hygiene

With over a century of experience, Fristam Pumps has become a benchmark for hygienic, reliable, and efficient pumping systems. Their pumps are made entirely from 316L stainless steel, ensuring maximum resistance to corrosion, high strength, and the best sanitary performance possible.

What makes them stand out is their smart design, precision internal clearances of up to 0.5 mm, internal seals that last even in extreme conditions, and a self-aligning shaft for easy installation. All pumps are fully CIP-compatible, meet global sanitary standards, and can be maintained without special tools.

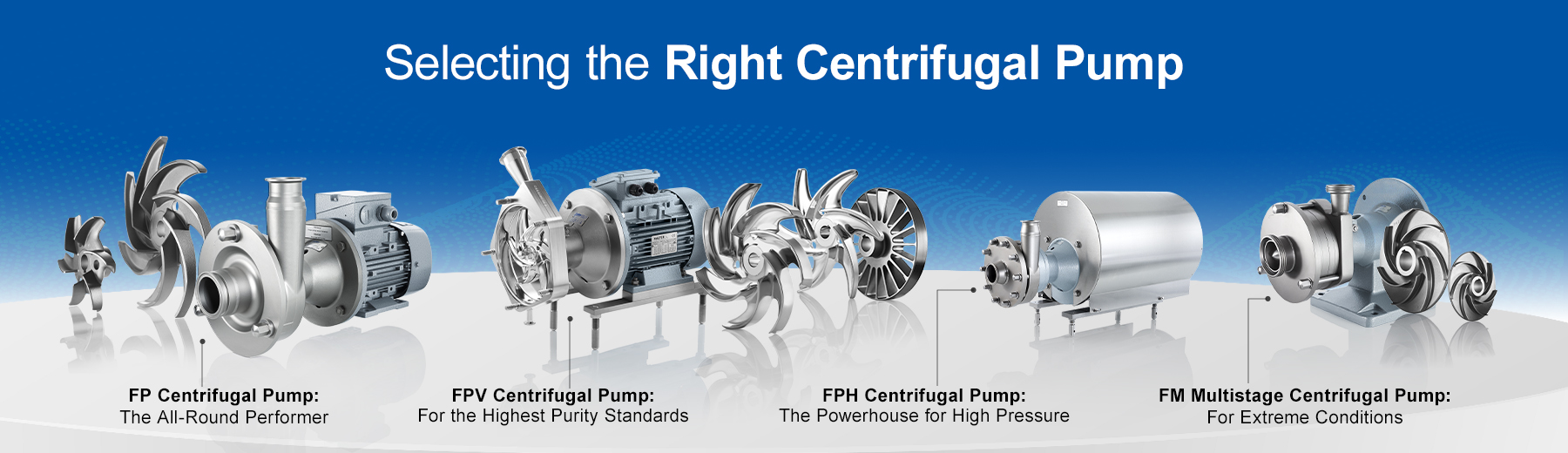

Let's take a closer look at Fristam's four standout models of centrifugal pumps for industrial applications:.

1. FP Centrifugal Pump: The All-Round Performer

The Fristam FP Series is a favourite across the dairy, chemical, and beverage industries. It's tough, reliable, and perfect for everyday hygienic processing.

Why it stands out:

The Fristam FP Series is a favourite across the dairy, chemical, and beverage industries. It's tough, reliable, and perfect for everyday hygienic processing.

- Available in 14 models

- Flow rates up to 550 m3/h

- Handles pressures up to 25 bar

- Energy-saving, gentle product handling

Its open impeller design ensures smooth transfer even when handling air, gases, or particles.

2. FPV Centrifugal Pump: For the Highest Purity Standards

The FPV Series is designed for pharmaceutical and biotech operations where sterility is critical. Each pump comes with full traceability for every part and material, ensuring complete transparency and reliability.

Why it stands out:

- Perfect for Water for Injection (WFI) systems

- Steam-in-place sterilization

- Long-lasting seal performance

- System pressures up to 25 bar

This pump keeps operations clean, safe, and contamination-free -- just what high-purity industries need.

3. FPH Centrifugal Pump: The Powerhouse for High Pressure

When your process demands strength, the FPH Centrifugal Pump delivers. Designed for high-pressure applications, it's ideal for use as a booster pump in filtration systems.

Why it stands out:

- System pressures up to 80 bar

- Flow rates up to 550 m3/h

- Low maintenance, durable build

It combines heavy-duty design with gentle product handling, giving you consistent performance under demanding conditions.

4. FM Multistage Centrifugal Pump: For Extreme Conditions

The FM Series is all about power and precision. With up to five impeller stages, it's built for high-pressure transfers of sensitive liquids.

Why it stands out:

- Discharge pressure up to 28 bar

- Flow rates up to 80 m3/h

- 2-5 stages for steady, smooth flow

It's strong, hygienic, and designed for the most challenging applications.

Tips for Selecting the Right Pump

- Know your process – flow, pressure, and product type.

- Always go for hygienic materials like 316L stainless steel

- Consider long-term efficiency, not just the initial cost.

- Choose trusted centrifugal pump manufacturers who understand your industry.

Since 1909, Fristam has been perfecting the art of pump design. Our pumps are trusted worldwide in the food and beverage industry, dairy plants, pharmaceutical facilities, and more. Every pump reflects the brand's commitment to quality, hygiene, and innovation.

With precision engineering and user-friendly maintenance, Fristam Centrifugal Pumps continue to set the standard for performance and reliability in hygienic processing.

Final Thoughts

Selecting the right pump can transform your operation – making it more efficient, reliable, and cost-effective. Fristam's FP, FPV, FPH, and FM pumps are designed to deliver exactly that.

If you're looking for a pump that combines long life, easy maintenance, and superior hygiene, Fristam's centrifugal pumps are the perfect fit. They don't just move your product, they move your business forward.

FAQs

1. What are the key factors to consider when selecting a centrifugal pump?

Flow rate, pressure, fluid type, material (like 316L stainless steel), energy efficiency, maintenance needs, and compliance with hygiene standards are crucial when choosing a centrifugal pump

2. How can I improve the lifespan of my centrifugal pump?

Regular maintenance, correct sizing, using clean-in-place (CIP) systems, monitoring vibration and temperature, and operating within recommended flow and pressure ranges help extend pump lifespan.

3. What is a centrifugal pump, and how does it work?

A centrifugal pump uses a rotating impeller to convert motor energy into fluid movement, efficiently transferring liquids by creating flow and pressure within the pump casing.