Fristam Pumps: A Game-Changing Solution to Customer Pain Points in the Hygienic Pumping Industry

March 13, 2025

The hygienic pumping industry plays a crucial role in sectors like food processing, dairy, pharmaceuticals, personal & home care, beverages & brewing and chemicals. All these businesses demand pumps to keep hygiene levels extremely high, make products secure, and promote operation efficiency at an optimal level. Yet companies suffer from potential contamination risks, heavy maintenance bills, poor cleanliness efficiency, and regulation difficulties.

Fristam pumps provide top-notch solutions that address these critical pain areas. Designed with regulatory compliance in pump design in mind, Fristam’s high-quality pumps help businesses achieve efficiency, hygiene, and cost savings. This blog highlights the common challenges in hygienic pumping and how Fristam’s pump compliance ensures superior performance across industries.

7 Pain Points in the Hygienic Pumping Industry

1. Product Contamination Risks

Product contamination risk in food, dairy, cosmetics, chemicals, pharmaceuticals, beverages, and brewing is a huge concern for customers, which is inevitable and may cause damage to brand image, various penalties and the recalling of product batches. Moreover, various factors are accountable during the operation for product contamination including failed seals, overheating during pumping, the selection of non-corrosive resistant material, and many pumps having rough surfaces or dead zone spaces in which microorganisms can cluster, so levels of contamination rise.

2. Pump’s Downtime & High Maintenance Expenses

Partial failure in pumps results in downtime, disrupting production timetables and raising the cost. Most of the pumps need to be repaired periodically because of wear and tear and inadequate lubrication, which incurs high maintenance costs. Customers need dependable pumps that have minimal maintenance charges and are capable of long-term operation.

3. Inefficient CIP/SIP Cleaning

Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) are essential for cleanliness. However, the majority of pumps are not designed for efficient CIP/SIP, leading to residue buildup and poor cleaning. Poor cleaning leads to contamination risk, extended cleaning time, and increased use of cleaning chemicals.

4. Handling of Shear-Sensitive & Viscous Products

Most of customers work into the business of viscous and shear-sensitive products like dairy creams, pharmaceutical gels, and food pastes. Ordinary pumps struggle to move these goods without altering their consistency and damaging of product integrity, which affects quality. customers require pumps that can move these products gently without degrading them.

5. Energy Inefficiency & High Operating Costs

Traditional pumps use a lot of energy, meaning that they cost more to power with electricity. Poor design results in waste power use, with implications both in operational cost and environmental sustainability. Customers need cost-saving, more efficient pumping options to save cost and improve effectiveness.

6. Lack of Versatility in Fluid Handling

Many industries require pumps that can handle different types of fluids, from thin liquids to thick pastes. However, using multiple pumps for different applications increases costs and complicates operations. A single, versatile pump that can handle multiple fluids is a more efficient solution.

7. Industrial Regulatory Compliance

Industries must comply with strict pump regulations and attain regulatory compliance in pump design to avoid legal issues and maintain product safety. Failure to meet industry standards for sanitary pumps can lead to financial losses and bad reputation.

How Fristam Pumps Solve These Challenges

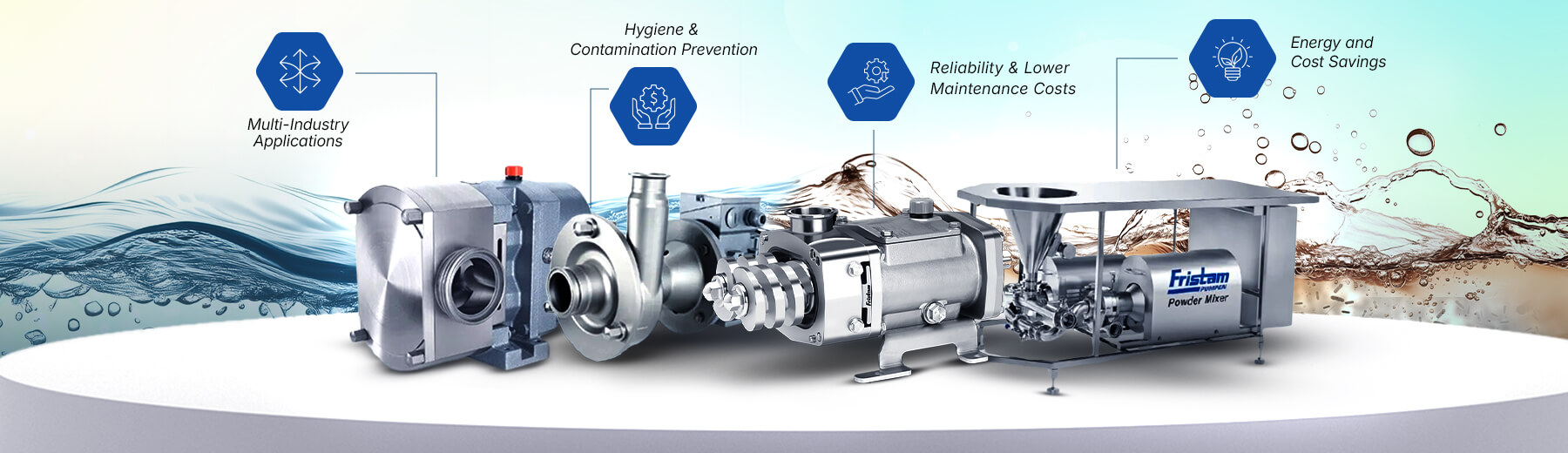

1. Hygiene & Contamination Prevention

Fristam pumps are built with smooth, crevice-free stainless-steel surfaces which are corrosive resistant to prevent any bacterial growth, these pumps have a uniquely high-standard design which is engineered with precision and accuracy to avoid product contamination risk. Moreover, Fristam pumps meet all necessary industrial compliances like 3-A and EHEDG making them suitable to be used as hygienic pumps for bio-pharmaceuticals, food, dairy, cosmetics, beverages & brewing, and chemical industries.

2. Reliability & Lower Maintenance Costs

Our pumps are built with premium-quality stainless steel, which provides durability and long service life. They possess a strong build that resists wear and tear, leading to fewer failures and reduced maintenance costs. That’s why using Fristam pumps in dairy processing and pharmaceutical production is an ideal choice.

3. Effective CIP & SIP Cleaning

Fristam pumps enable total Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) to enable thorough cleaning without dismantling. These processes save time, replacement parts and labor costs, and ensure compliance with food safety solutions with Fristam pumps.

4. Viscous Liquid Handling

Our pumps are engineered to handle thick, shear-sensitive material without compromising quality. The low-pumping action of Fristam’s technology in bio-pharmaceutical production, cosmetic creams, and food paste makes them ideal choice.

5. Energy and Cost Savings

Fristam pumps feature cutting-edge impeller and motor designs that optimize energy usage. Customers using Fristam solutions reduce electricity use up to 90-100% as per Fristam’s survey rather using outdated old technology and daily saved extra operational 4-5 hours and enjoy improved efficiency, becoming a major part of sustainability.

6. Multi-Industry Applications

Fristam’s pumps are versatile and adaptable to be used for various types of fluids. They are used widely in dairy processing, personal & home care product pumping solutions, chemical industry pumping challenges, bio-pharmaceutical and food processing. With their adaptability, the companies can streamline operations with one efficient pump.

7. Guaranteed Compliance with Industry Regulations

Fristam ensures that its pumps meet all sanitary pump industry standards; 3-A and EHEDG, eliminating the risk of non-compliance. With strict design regulatory compliance, customers work safely without any legal concerns.

Conclusion

The sanitary pumping industry is plagued by a multitude of problems like contamination risks, high maintenance costs, poor cleansing efficiency, energy usage, and regulatory complications. Fristam pumps offer solutions that enhance hygiene, reduce equipment downtime, minimal operation & maintenance cost, and saved energy consumption.

Fristam delivers compliant and efficient solutions for different sectors. With Fristam’s dairy processing pumps, food safety solutions, and bio-pharmaceutical production, businesses can ensure quality, safety, and efficiency in fluid handling.

For Indian industries looking for high-performance hygienic pumps, Fristam Pumps delivers innovative solutions that suit industry requirements.

Visit our website today and explore our line of sanitary pumping solutions!